Altec RAD-0040A - 40 CFM Non Cycling Refrigerated Air Dryer, 115V

FREE SHIPPING

On All Orders Over $149.00

Satisfaction Guaranteed

Easy Exchanges & Returns

Secure checkout

Protected By SSL

Description

Altec AIR RAD Series Non-Cycling Refrigerated Air Dryers, proudly Made in the USA. These dryers offer a dependable solution for maintaining a consistent and reliable supply of dry air for your compressed air system. Crafted with precision and durability in mind, these dryers are engineered with quality components to ensure long-lasting performance.

Key Features:

- Consistent & Reliable Dry Air - Achieve ISO Class 5 air quality consistently to meet your industry standards.

- Compact All-Aluminum Heat Exchanger Modules - Designed for efficiency with minimal pressure drops, ensuring optimal performance.

- Programmable Automatic Electronic Drains - Enhance maintenance efficiency and system reliability with automated drainage.

- Easy-Access Cabinet Design - Simplify maintenance and serviceability with a user-friendly design.

- Suction & Discharge Pressure Gauges - Monitor the refrigeration system effortlessly for peace of mind.

- Top Mounted Inlet & Outlet Connections - Facilitate easy installation of the dryer, filters, and bypass valves for a seamless setup.

- ETL Listed Configurations (Pending) - Pending ETL listing ensures adherence to safety standards, providing added assurance.

Invest in Altec AIR’s RAD Series Non-Cycling Refrigerated Air Dryers for unparalleled performance and reliability in your compressed air system. Experience the difference quality craftsmanship makes. Order yours now and elevate your air quality with confidence.

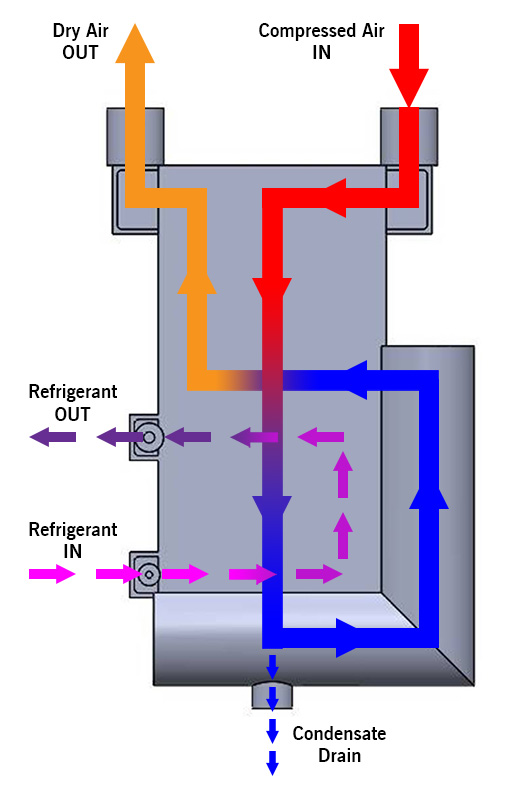

Refrigeration Air Drying Process

-

Altec AIR Refrigerated Air Dryers stand out as essential components in ensuring optimal air quality for your compressed air system. Utilizing refrigeration cooling technology, these dryers efficiently condense moisture, effectively removing it from your system. Let's delve into the intricacies of their operation:

-

Pre-cooling Process: Warm, moisture-laden air enters a pre-cooler/re-heater heat exchanger at the dryer inlet. Here, it encounters outgoing cold air, initiating the pre-cooling process to regulate its temperature.

-

Air to Refrigerant Heat Exchange: The pre-cooled air then advances to the air to refrigerant heat exchanger, where it undergoes further cooling. This stage brings the air to its lowest temperature point, facilitating moisture condensation.

-

Moisture Removal: As the air cools, the moisture within it transitions from vapor to liquid form. This condensed moisture is efficiently removed by a robust stainless-steel mesh separator and is discharged from the dryer through an automatic drain valve.

-

Re-heating Mechanism: Following moisture removal, the now cold air undergoes re-heating by incoming warm air. This re-heating process occurs as the air circulates back through the pre-cooler/re-heater, ensuring optimal temperature regulation.

-

Clean, Dry Air Output: The culmination of this process results in the production of warm, clean, and dry air, ready for immediate utilization by your compressed air system.

Incorporating Altec AIR Refrigerated Air Dryers into your setup ensures not only the elimination of moisture but also the delivery of high-quality, conditioned air to meet the demanding requirements of your compressed air applications. Experience the reliability and efficiency of Altec AIR technology today.

Don't Forget Your Filters!!!

Protect your Investment and get the properly sized and compatible Alec Air Filtration Kit. There are 3 choices for your level of protection needed.

(1) Prefilter & (1) Afterfilter: AR11-0040

-