When it comes to setting up a compressed air system for your business, the piping material you choose plays a critical role in the system's safety, efficiency, and longevity. While PVC piping may seem like an appealing option due to its low cost and ease of installation, it presents severe risks that can't be ignored. In this blog, we'll delve into why using PVC piping in compressed air piping applications is a dangerous and non-recommended practice.

The Risks of Using PVC for Compressed Air Applications

At first glance, PVC piping seems versatile and cost-effective, commonly used to transport liquids like water in various applications. But what works for water doesn't necessarily work for compressed air. Unlike water, compressed air can store a significant amount of energy, making PVC a hazardous choice for this purpose.

When you use PVC piping for compressed air, the pipe can burst under high pressure, essentially acting like a shrapnel bomb. This can result in severe injuries, or even death, for anyone nearby. Additionally, most PVC pipes have a maximum temperature rating of around 140°F. Once the air flowing through reaches 110°F, the pipe's pressure rating gets cut in half. In other words, a pipe rated for 150 psi is suddenly only safe for 75 psi, increasing the likelihood of an explosion.

Furthermore, PVC material deteriorates over time, becoming brittle and heightening the risk of leaks or explosions as it ages.

Compliance and Regulations

Using PVC piping for compressed air is not only risky but also illegal in many jurisdictions. OSHA (Occupational Safety and Health Administration) standards expressly forbid the use of PVC for above-ground compressed air and gas transportation. Failure to comply could lead to heavy fines and even the shutdown of your business for repeated violations. The Plastic Pipe and Fittings Association also discourages using compressed air or inert gases in plastic piping systems. To further deter its use, many PVC pipe manufacturers include warning labels stating the pipe should not be used for compressed air or gas transport due to the enormous safety risks involved.

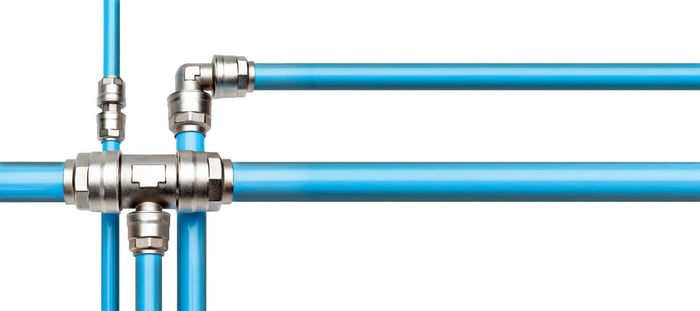

The Safer Alternative: Aluminum Piping

So, what should you use instead of PVC for your compressed air system? The answer is aluminum piping. Not only is it lightweight and easy to handle, but it is also non-corrosive and cost-efficient. At Compressed Air Advisors Online, we offer premium aluminum piping solutions that are not just easy to install but also come backed with a lifetime warranty.

Conclusion

While PVC may seem like a cheap and convenient option for transporting compressed air, the risks are too high to ignore. Between the legal repercussions and the danger to human life, it's simply not worth the gamble. Contact Compressed Air Advisors Online today to explore safer, OSHA-compliant alternatives for your compressed air transportation needs.

Looking for expert advice and premium products for your compressed air system? Look no further than Compressed Air Advisors Online, where we feature a wide range of options from top manufacturers such as Chicago Pneumatic, Champion, FS Curtis, and more. Our end goal is to provide you with the best solutions available, making your operations safer, more efficient, and cost-effective.

Check out Compressed Air Advisors Online's complete offering of Aluminum Compressed Air Piping by clicking HERE.